Published On: 07-Feb-2022

Get ready for a phase change By using the non woven bag for all the needs.

Nonwoven fabric is a cloth like material which is commonly used as a raw material in shopping bags, masks, diapers, PPE kits, hospital aprons, bed sheets in hospitals among many other applications.

Nonwoven fabric is most commonly made using Polypropylene (PP) granules which is an inexpensive thermoplastic polymer. In terms of chemical composition of PP, it is a downstream petrochemical product. Being thermoplastic in nature, PP is highly useful because it can be heated, cooled, and reheated without causing significant degradation to its base composition. PP is also viewed as one of the most promising goods because of its physical properties, adaptability, and environmentally friendly record. PP can be blended with different types of biodegradable polymers such as polylactic acid (PLA) and thermoplastic starch (TPS).[i]

If nonwoven fabric is made from petrochemical product then isn’t it as bad as plastic?

The answer is a big NO. At Bags Guru, we have done a comparative analysis of various materials used to make bags. Nonwoven bags prove to be the most eco-friendly option for shopping bags. It beats paper and jute bags by a long margin.

Everyday clothes that we wear are made from polyester (PET) which in its entirety is 100% plastic. But it does not count towards plastic pollution because we re-use the clothes. Similarly, non-woven bags are highly re-usable and 100% recyclable. Paper bags are thrown away after using 2-3 times whereas nonwoven bags are re-used ~50 times. Therefore, 1 nonwoven bag does the work of 20 paper bags.

Following are the reasons one should opt for non-woven bags over plastic bags, paper bags and jute bags:

- DURABLE

As mentioned above, paper bags are thrown away after using 2-3 times, whereas nonwoven bags are re-used ~125 times. 1 nonwoven bag does the work of 20 paper bags. Thus, they are better than single use plastic bags & use-and-throw paper bags. Non woven tote bags are much stronger and durable in comparison to paper bags.

- STRONG

Nonwoven bags are capable of carrying heavy items in regular day-to-day life. Non woven bags can carry up to 15 kg weight with ease. A paper bag can never achieve this reliability. The bags made by Bags Guru have been tested to carry even 20 kg of weight. We put 20 L water jar in the bag to test the capacity.

Shopping bags are a free branding and advertisement commodity for businesses. And who doesn’t love to blend style and vibrancy in their brand promotion. Unlike paper and jute bags, nonwoven bags comes in a variety of colours with stylish printing options. This feature appeals to shop owners, and thus nonwoven bags do the work of carrying products as well as promoting the brand.

- NO DRAIN CONGESTION

Mumbai floods are a yearly phenomenon. But heavy rains isn’t the only reason behind it. Congestion of drainage system further aggravates the problem. Plastic bags are the biggest culprit in blocking the drainage system. Nonwoven bags are permeable and allow water and air to pass through them. Thus, in comparison to plastic bags, they are less probable to block drainage systems.[i]

Nonwoven bags are low energy recyclable, this means that the process of breaking nonwoven into smaller pellets and then re-making them into bags consumes very little energy and causes no pollution. Whereas paper and jute bags are high energy recyclable materials as they consume lot of water and excessive heat during the recycling process.

- BUDGET FRIENDLY

Let’s face it, paper and jute bags are super expensive. The government may promote the use of paper and jute bags, but only shop owners know the heavy costs they need to pay for single use paper bags and extremely expensive jute bags.

Non woven bags on the other hand are cheaper than paper bags (in terms of the same bag volume) and since they are much more re-usable, non woven bags have high value for money.

- PAPER CATCHES FIRE FASTER THAN FABRIC

Paper bags have been a reason of spreading fire in uncountable incidents. It’s like storing kerosene oil. Think twice before storing paper bags in your godown. On the other hand non woven bags are not as flammable as paper bags and are safer to store. Picture Courtesy.

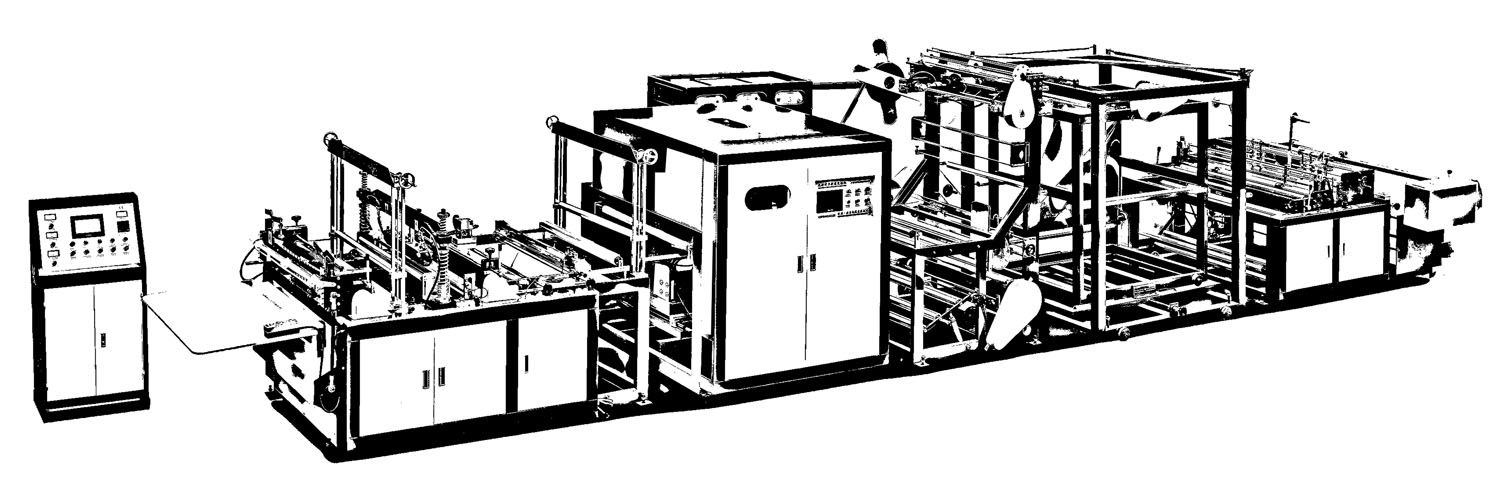

- FAST PRODUCTION

- Diwali sale season (October/November) is a time that every shop owner eagerly waits for throughout the year. Be it textile merchants, sweet shops, electronic shops, mobile shops or jewellers. They plan for packaging materials months in advance around the month of August.

- Jute and cotton bags require manual labour to ‘stitch’ the bags which is a slow mode of manufacturing. There is no way that these bags can meet the demands of a sale season. Thus they become unreliable in the most important times. [i]

- Paper bags, on the other hand, have poor shelf life and thus bags made in August can’t be used in October end. Although there is high automation in paper bag making industry, they get very limited time to meet the demand of the sale season.

- Non woven bags come to rescue during this time. It is a very common practice of shop owners to order ample quantity of nonwoven bags before Diwali so that packaging is the least of their worries. Nonwoven bags have long shelf life and can be made with high levels of automation. At Bags Guru, we have 100% automatic machines to make the bags.

CONCLUDING THOUGHTS:

The sooner people understand and accept the benefits of nonwoven bags, the better it is for the world. Considering all the reasons mentioned above, it is clear that nonwoven is the best solution to plastic pollution. It is advisable to switch to non-woven bags instead of plastic, paper or jute bags.

With Bags Guru, shift to the resilient and eco friendly Non Woven bags and contribute to the well-being of the environment.

This article is written by Bags Guru founder, Ankit Parsurampuria. Ankit is a graduate from IIT Delhi and is working in the packaging industry since 2016.