Published On: 01-Feb-2022

Shifting from paper/plastic bag to alternative bag? Know whether to go for woven or non woven bags.

As the world is moving towards the regime of PLASTIC BAN, businesses have begun to find cost effective yet eco-friendly ways of making bags and packaging items for delivering products in a safe and sustainable manner.

Non woven fabric has proven to be the go-to option for almost every product category due to the NO PLASTIC movement. A major shift has been seen in the shopping bags industry which is gradually adapting to non woven and woven PP bags.

Both woven and non woven bags are more durable and sustainable in comparison to polythene bags made from PET. Non woven bags have a textile feel and are fall in the re-usable bags category. They can be washed in washing machines just like clothes. A wide range of printing options are available with non woven bags and thus these bags are gaining popularity among retail shops in India and abroad.

Woven Vs Non Woven Bags?

Material wise, both woven and non woven polypropylene bags are created from the same polypropylene (PP) granules but with different grades. The only difference is the process to manufacture the fabric.

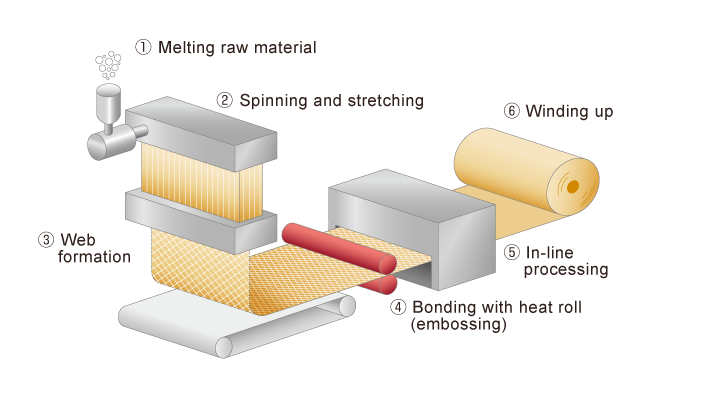

Nonwoven fabric is made using multiple steps. First, PP granules are melted and passed through a die to form thin threads. These fibrous threaded structures are entangled and bonded together by spreading uniformly on a running conveyor belt. This spreading process is a multi-layer process that finally gives it a fabric-like finish. Additives can be added to re-engineer nonwoven fabric to impart qualities like making it waterproof, water-resistant, water repellent, etc.

The Advantage Of Non Woven Fabric is:

- Ease of manufacturing

- Easy to add features to the fabric which make it suitable for a large variety of applications – healthcare, agriculture, construction, packaging, etc. This is also called ‘application-specific engineering’

- Air and water permeable. The fabric can be re-engineered to make it waterproof as well.

Non Woven Fabric - Picture Courtesy

Non Woven Production Line - Picture Courtesy

Woven fabric is made from PP threads (yarn) in a circular loom setup. The warp-weft system using spindle and shuttle leads to the creation of woven fabric from the yarn. The manufacturing process is slow, thus companies need to install multiple copies of the machine to meet the requirements.

Woven PP Fabric Making Process - Picture Courtesy

Woven PP Fabric Bag - Picture Courtesy

Making bags using woven PP is slightly more complicated compared to non woven bags. Although, with the advent of new technologies, 100% automation is possible to make both the variety of bags. Since woven PP has found vast usage in cement and rice bags, they do not appeal to the shopping bag category due to its rugged appearance. In terms of eco-friendliness, both the bags are 100% recyclable. But because non woven fabric allows air and water to pass through, it is advantageous to be used in flood prone areas (e.g. Mumbai) as non woven bags don’t lead to blockage of drains.

Advantage of nonwoven bags:

- durable

- eco-friendly

- 100% recyclable

- easy customization

- machine washable, thus high re-usability

- strong – bags can easily take upto 15 kg of weight

- air and water can pass through, therefore no blockage of drains

- Laminated nonwoven fabric can be used to make the bag water proof

All these qualities make non woven bags an ideal alternative for women’s shopping bags, groceries bags, fashion apparel bags, jewellery bags, wedding bags, etc.

As a business owner, this is the right time for you to make a shift from plastic bags to non woven bags. We, at Bags Guru, will help you with all your non woven and woven PP bag requirements.

This article is written by Bags Guru founder, Ankit Parsurampuria. Ankit is a graduate from IIT Delhi and is working in the packaging industry since 2016.